|

|

DeFelsko FNDS1-G PosiTector 6000 FNDS1 Coating Thickness Gauge with Standard Body, Duplex Coatings Cabled Probe, Measures Coatings on All Metals, 0-60 mils

Price: $ 1,410.00

Model: FNDS with Standard (1) Body

Range: 0-60 mils

In Duplex mode, the DeFelsko PosiTector 6000 Standard FNDS1 Coating Thickness Gauges utilizes both magnetic (ferrous) and eddy current (non-ferrous) principles simultaneously to calculate and display the individual paint and zinc layer thicknesses.

The DeFelsko FNDS1 Positector 6000 FNDS1 Standard Coating Thickness Gauge is a precise, rugged tester designed to measure coating thickness on all metals accurately and quickly using magnetic or eddy current principles. The PosiTector 6000 FNDS probe measures the individual thicknesses of both the paint and the zinc layers in a duplex coating system with a single reading. Duplex coating systems use a combination of two corrosion protection systems typically paint or powder coating over galvanized steel (hot-dip, electro or zinc spray metallizing). The resultant corrosion protection is superior to either protection system used independently. In Duplex mode, the PosiTector 6000 FNDS utilizes both magnetic (ferrous) and eddy current (non-ferrous) principles simultaneously to calculate and display the individual paint and zinc layer thicknesses. The magnetic principle is used to measure the combined paint/zinc thickness over the ferrous substrate, and the eddy current principle is used to measure the paint thickness over the non-ferrous zinc coating. The zinc thickness is calculated by subtracting the paint thickness from the combined paint/zinc thickness measurement. The DeFelsko FNDS1 Positector 6000 FNDS1 Standard Coating Thickness Gauge has a large 2.8" impact resistant color touchscreen with redesigned keypad for quick menu navigation, 1,000 in one group memory reading storage capacity and USB data output.

Kit Contents

The DeFelsko PosiTector 6000 FNDS 1 Standard Coating Thickness Gage Kit includes everything needed for testing: - PosiTector Standard Gage Body BDYSTD

- PosiTector 6000 Probe FNDS

- Precision Plastic Shim(s)

- Protective Rubber Holster

- Wrist Strap and Protective Lens Shield

- 3 AAA Alkaline Batteries

- PosiSoft Software and USB Cable

- Long Form Certificate of Calibration Traceable to NIST or PTB

- Protective Carrying Case and Instructions

- Two (2) Year Warranty

|  |

Features

Simple - Fast measurement speed - 60+ readings per minute. Enhanced FAST mode - 90+ readings per minute for quick inspection.

- Ready to measure - no adjustment required for most applications

- NEW Larger 2.8" impact resistant color touchscreen with redesigned keypad for quick menu navigation

- NEW On-gage help explains menu items at the touch of a button

- Flashing display - ideal in a noisy environment

- RESET feature instantly restores factory settings

Durable - NEW Weatherproof, dustproof, and water-resistant - IP65-rated enclosure

- NEW Ergonomic design with durable rubberized grip

- Wear-resistant probe tip

- Shock-absorbing, protective rubber holster for added impact resistance

- Two year warranty on gage body AND probe

Accurate - Certificate of Calibration showing traceability to NIST or PTB included

- Built-in temperature compensation ensures measurement accuracy

- Hi-RES mode increases displayed resolution for precision applications

- Conforms to national and international standards including ISO and ASTM

Versatile - PosiTector body accepts all PosiTector 6000, 200, DPM, IRT, RTR, SPG, SST, SHD, BHI, and UTG probes easily converting from a coating thickness gage to a dew point meter, surface profile gage, soluble salt tester, ultrasonic wall thickness gage, or hardness tester

- Multiple Calibration adjustment options including 1 point, 2 point, and ISO 19840 correction factors

- Selectable display languages

- NEW Auto rotating display with Flip Lock

- Extended cables available (up to 75 m/250 ft) for underwater or remote measuring

- Mils/Microns/mm switchable

Powerful - Statistics mode continually displays/updates average, standard deviation, min/max and number of readings while measuring

- NEW Screen Capture - save 100 screen images for record keeping and review

- HiLo alarm audibly and visibly alerts when measurements exceed user-specified limits

- NEW Instant-on feature quickly powers up the gage if recently powered down

- NEW Up to 30% longer battery life

- USB port for fast, simple connection to a PC and to supply continuous power. USB cable included.

- Every stored measurement is date and time stamped

- Software Updates via web keep your gage current

- Software Solutions for viewing, analyzing & reporting data

Standard Model Features

- Includes ALL features as shown above plus:

- Storage of 1,000 readings per probe - stored readings can be viewed or downloaded

Specifications

| Measuring principle | magnetic induction principle (Ferrous)

eddy-current principle (Non-Ferrous) | | Display | High contrast, reversible color LCD | | Data Output | USB - "1" & "3" Models

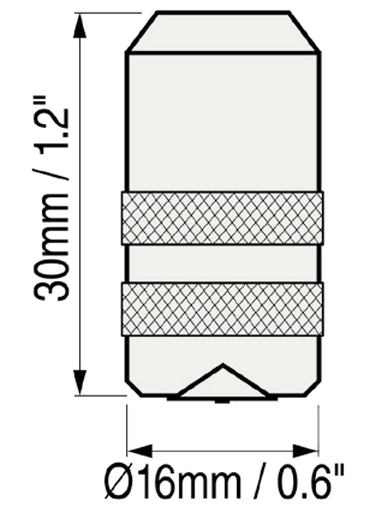

Bluetooth - "3" Models | | Power | 3 AAA batteries, Included | | Dimensions | 5.75" x 2.5" x 1.2" (146 x 64 x 31 mm) | | Weight | 5.8 oz. (165 g) without batteries | | Protection Class | Meets or exceeds IP5X, Solvent, acid, oil, water & dust resistant | | Warranty | 2 Years | | Calibration Certificate | Certificate of Calibration showing traceability to NIST included |

Probe Specifications

| Range | 0 - 60 mils | 0 - 1500 | 0| Minimum Zinc Thickness | 0.5 mil (13 ) | | Paint Layer Accuracy Mils | (0.05 mils + 1%) 0 - 2 mils | | (0.1 mils + 1%) > 2 mils | | Paint Layer Accuracy Microns | (1 + 1%) 0 - 50 | | (2 + 1%) > 50 | | Zinc Layer Accuracy Mils | (0.1 mils + 1%) 0.5 - 2 mils | | (0.2 mils + 1%) > 2 mils | | Zinc Layer Accuracy Microns | (2 um + 1%) 13 - 50 um | | (4 um + 1%) > 50 um |

The PosiTector 6000 FNDS probe measures the individual thicknesses of both the paint and the zinc layers in a duplex coating system with a single reading. Duplex coating systems use a combination of two corrosion protection systems typically paint or powder coating over galvanized steel (hot-dip, electro or zinc spray metallizing). The resultant corrosion protection is superior to either protection system used independently. In Duplex mode, the PosiTector 6000 FNDS utilizes both magnetic (ferrous) and eddy current (non-ferrous) principles simultaneously to calculate and display the individual paint and zinc layer thicknesses. The magnetic principle is used to measure the combined paint/zinc thickness over the ferrous substrate, and the eddy current principle is used to measure the paint thickness over the non-ferrous zinc coating. The zinc thickness is calculated by subtracting the paint thickness from the combined paint/zinc thickness measurement. When disabled, the gage will operate like a conventional combination ferrous/non-ferrous instrument (similar to PosiTector 6000 FNS probe). Ideal for measuring non-magnetic coatings over steel and non-conductive coatings over non-ferrous metal substrates. Compatible with PosiTector Advanced (serial numbers 730,000+) and PosiTector Standard gage bodies with a color display. A Simple gage update may be required.

PosiSoft Suite of Software

Four FREE and unique ways to view and report your PosiTector and PosiTest data. Learn More

Related Products Related Products

Downloads

|

|

|